The Different Types of Heat Exchangers in Industries

Heat exchangers are typical bits of a couple of contraptions and mechanical assembly used in various endeavors today. Profound organizations, for instance, petroleum gas plants, power plants, sewage treatment workplaces and petrol handling plants use them in their provisions. The equipment used in such undertakings not simply need predictable examination, they moreover need constant cooling. Heat exchangers play out this occupation for them. Heat exchangers are devices that are acquainted with work with useful heat moves beginning with one medium then onto the following. These mediums are generally as water and various liquids. The cycle incorporates liquids being secluded by a slight solid divider that will keep it away from being in direct contact with each other. There are furthermore the heat exchangers that let these liquids mix during the trade cycle.

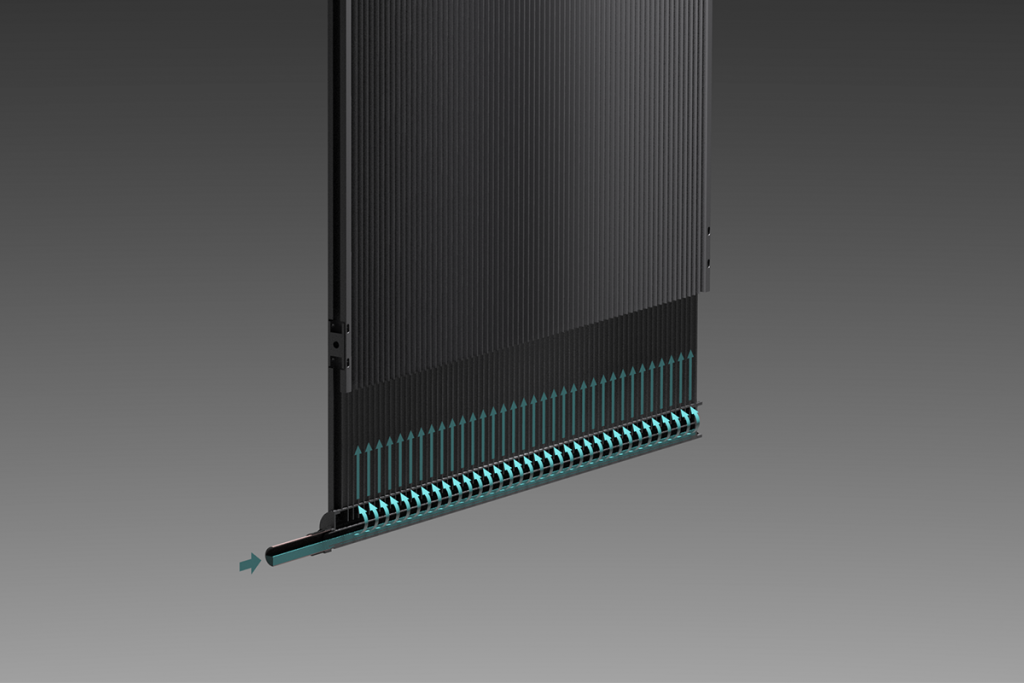

These sorts have a couple of plates that are ordinarily small and to some degree segregated when placed in the machines. They are regularly gigantic in surface locale which engages it to manage heat moves between mediums with next to no issue. Appeared differently in relation to the shell and chamber, the plate heat exchanger should be more reasonable in light of the fact that it incorporates a stacked-plate course of action. All through the long haul, many machines have changed over to this sort because of its sensibility and capability of use. In machines like a refrigerator, these can either be one of two sorts plunge brazed or vacuum-brazed. These devices can similarly be portrayed taking into account the sorts of plates that they use. They can in like manner be isolated by the plans of the plate being used. A couple of plates can have their own momentous plans with different stamps, models, cutting edges or indents and look at this site https://www.kaltra.com/microchannel-heat-exchangers. A plate sharp edge uses sets of passages, generally called sandwich segments, which increase the adequacy of the whole machine. Different edge courses of action are remembered for a plate balance heat exchanger. These consolidate straight sharp edges, wavy equilibriums and offset adjusts.

The arrangement of this particular exchanger furthermore has some cross stream and counter stream plans. The higher heat move capability displayed by a plate balance exchanger can be credited to the aluminum combination which it is made of. This particular mix enables the plate cutting edge to work at a much lower temperature all while reducing the substantialness of the stuff it was acquainted with. This type can be regularly found on machines that are used for the patterns of combustible gas plants, liquefaction plants, air separation plants and some more. It can in like manner be found inside motor engines. This sort of heat exchanger uses moderate fluid and solid during its heat move processes. Adiabatic wheels involve a colossal wheel alongside amazingly fine strings that turn through the hot and cold mediums. This enables the viable heat move between the two fluids.